Understanding Digital Image Correlation: Everything You Need To Know

BlogIntroduction to Digital Image Correlation

What is Digital Image Correlation?

Digital Image Correlation( DIC) is an optic system used to measure full- field deportations and strains on the face of an object. It involves assaying images before and after distortion to track changes and calculate strain fields.

History and Development

DIC ways began in the late 20th century with advancements in digital imaging and computing capabilities. originally used in material wisdom and biomechanics, DIC has since expanded into colorful diligence for its precise dimension capabilities.

Applications of Digital Image Correlation

Structural Analysis

Aerospace Industry Applications

In aerospace, DIC helps analyze stress distributions and material behavior in components like wings and fuselages during testing and operational phases. It ensures structural integrity and performance optimization.

Civil Engineering Applications

In civil engineering, DIC is used to monitor infrastructure such as bridges and buildings for deformations under different loads and environmental conditions. It aids in structural health monitoring and maintenance planning.

Biomechanics and Healthcare

Orthopedic Research

DIC plays a crucial role in orthopedic research by measuring bone deformations and joint movements. It helps in understanding the biomechanics of human movement and developing better medical treatments.

Biomechanical Studies

In sports wisdom and biomechanics, DIC is used to dissect muscle strains, common movements, and outfit performance. It contributes to perfecting athletic performance and injury forestallment strategies.

How Digital Image Correlation Works

Principles of Operation

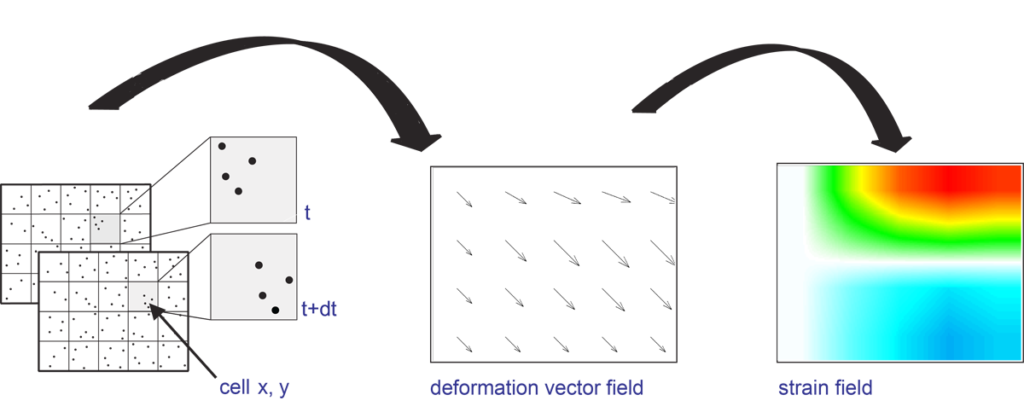

Image Acquisition

DIC begins with capturing high-resolution images of the object’s surface using cameras. These images serve as the baseline for deformation analysis.

Feature Tracking (H3)

Next, specialized software tracks identifiable features (such as speckle patterns) on the object’s surface across successive images. It monitors their displacement and deformation under load.

Deformation Calculation

Using algorithms, DIC calculates the strain and deformation fields based on the displacements of tracked features. It provides detailed insights into how materials behave under stress.

Advantages Over Traditional Methods

High Accuracy and Precision

DIC offers superior accuracy compared to traditional strain gauges or extensometers, as it captures full-field data rather than point measurements.

Non-invasive Nature

Unlike strain gauges that require physical attachment to the object, DIC is non-contact and non-invasive, making it suitable for delicate or moving surfaces.

Real-time Data Capture

DIC provides real-time data during testing, allowing engineers and researchers to monitor structural changes immediately and adjust experiments accordingly.

Challenges and Limitations

Environmental Factors

Lighting Conditions

Changes in lighting can affect image quality and tracking accuracy, requiring controlled environments or advanced lighting setups.

Surface Texture

Smooth or reflective surfaces may pose challenges for DIC, as they can obscure or distort the speckle patterns used for tracking.

Computational Demands

Processing Power

DIC analysis involves intensive computational tasks, requiring powerful hardware and software to process large datasets within reasonable timeframes.

Data Storage Requirements

Capturing high-resolution images and storing them for analysis can lead to significant data storage demands, necessitating efficient storage solutions.

Innovations in Digital Image Correlation

Advanced Algorithms and Software

Machine Learning Integration

Recent advancements integrate machine learning algorithms to automate feature tracking and enhance measurement accuracy in complex scenarios.

3D DIC Techniques

Traditional DIC methods are 2D, but ongoing research focuses on developing 3D DIC techniques for volumetric strain analysis and spatial deformation tracking.

Future Trends and Applications

Industry 4.0 and Automation

Robotics and Automation

In Industry 4.0, DIC contributes to automated quality control and inspection processes in manufacturing, ensuring product consistency and reliability.

Smart Manufacturing

DIC enables real-time feedback in smart manufacturing environments, optimizing production processes and minimizing defects through continuous monitoring.

Healthcare Advancements

Personalized Medicine

In healthcare, DIC supports personalized medicine by analyzing tissue deformations and optimizing medical device designs tailored to individual patient needs.

Prosthetic Design

DIC aids in developing advanced prosthetics by simulating biomechanical interactions and ensuring optimal fit and functionality for users.

Conclusion

Digital Image Correlation( DIC) stands at the van of ultramodern dimension technologies, offering unequaled perceptivity into structural geste , biomechanics, and material wisdom. Despite challenges like environmental factors and computational demands, DIC continues to evolve with inventions in software, tackle, and operation disciplines. Its future holds pledge in enhancing robotization, healthcare results, and manufacturing processes, making it an necessary tool in exploration and assiduity.

FAQs About Digital Image Correlation

1. What is digital image correlation used for? Digital image correlation is used to measure full-field displacement and strain in materials and structures, aiding in research, testing, and quality control across industries.

2. How does digital image correlation work? It works by analyzing images before and after deformation to track displacements of features, calculating strains and stresses based on pixel shifts.

3. What are the benefits of digital image correlation over traditional methods? It offers higher accuracy, non-invasive testing, and real-time data capture compared to traditional strain measurement techniques.

4. What are the challenges of using digital image correlation? Challenges include environmental factors affecting image quality, such as lighting and surface conditions, as well as the computational resources required for data processing.

5. Where is digital image correlation technology heading in the future? Future advancements may include integrating machine learning for improved analysis, expanding into 3D measurements, and applications in smart manufacturing and healthcare.

For more AI updates read our latest posts…

Thank you so much for your kindness and support!

Warm regards